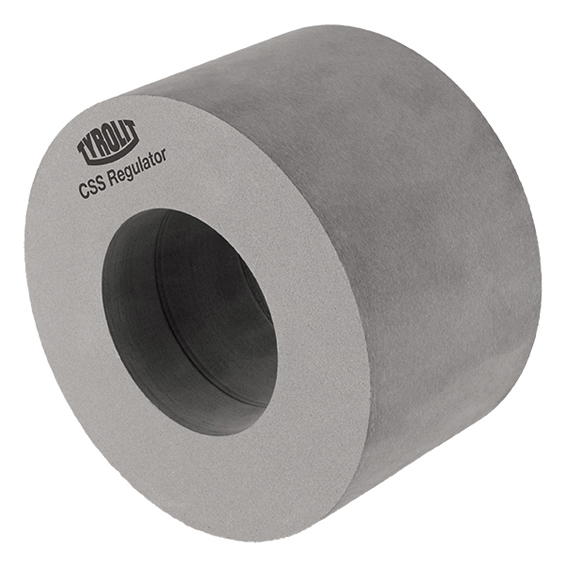

Regulating wheels are maybe the most important key elements of centerless grinding application. These wheels aims only to grip and slow down the workpiece, not to remove material. So regulating wheels are made of rubber to reach this aim not to remove material from workpiece.

Sometimes local manufacturers offers bacalite grinding wheels as substitution. But the biggest negative effect of these bacalite wheels are that they remove material from workpiece. It causes geometrical problems such as ovalness and cylindiricality as well as worse surface quality.

Also bacalite wheels has generally four times lower service life comparing rubber regulating wheels.